Content

❙ Specifications of Yamaha Chip Mounter

| M20 | |

|---|---|

| Board size(with buffer unused) | Min. L50 x W30mm to Max. L1,480 x W510mm*1 |

| Board size(with input and output buffers used) | Min. L50 x W30mm to Max. L540 x W510mm |

| Board thickness | 0.4 - 4.8mm |

| Board flow direction | Left to right (Std) |

| Board transfer speed | Max 900mm/sec |

| Placement speed (4 heads + 1 theta) Opt. Cond. | 0.15sec/CHIP (24,000CPH) |

| Placement speed (4 heads + 4 theta) Opt. Cond. | 0.15sec/CHIP (24,000CPH) |

| Placement speed (6 heads + 2 theta) Opt. Cond. | 0.12sec/CHIP (30,000CPH)*2 |

| Placement speed (4 heads + 1 theta) IPC9850 | 19,000CPH |

| Placement speed (4 heads + 4 theta) IPC9850 | 19,000CPH |

| Placement speed (6 heads + 2 theta) IPC9850 | 23,000CPH*2 |

| Placement accuracy A (μ+3σ) | CHIP +/-0.040mm |

| Placement accuracy B (μ+3σ) | IC +/-0.025mm |

| Placement angle | +/-180 degrees |

| Z axis control | AC servo motor |

| Theta axis control | AC servo motor |

| Component height | Max 30mm*3 (Pre-placed components: max 25mm) |

| Applicable components | 0402 to 120x90mm, BGA, CSP, connector, etc. |

| Component package | 8 - 56mm tape (F1/F2 Feeders), 8 - 88mm tape (F3 Electric Feeders), stick, tray |

| Drawback check | Vacuum check and vision check |

| Screen language | English, Chinese, Korean, Japanese |

| Board positioning | Board grip unit, front reference, auto conveyor width adjustment |

| Component types | Max 144 types (8mm tape), 36 lanes x 4 |

| Transfer height | 900 +/- 20mm |

| Machine dimensions, weight | L1750xD1750xH1420mm, Approx. 1450kg |

| Power |

3-phase 200/208/220/240/380/400/416/440V +/-10% (Transformer included), 50/60Hz |

| Max consumption, capacity | 1.1kW, 5.9kVA |

| Air pressure, consumption | 0.45Mpa, 50(4 heads) or 75(6 heads) L/min A.N.R. |

*1 Max. 950mm for 6-head configuration

Successful Experience:

Eta's Customer In 35 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

❙ ETA Exhibition

❙ Chip Shooter Certificate

❙ ETA Global Service

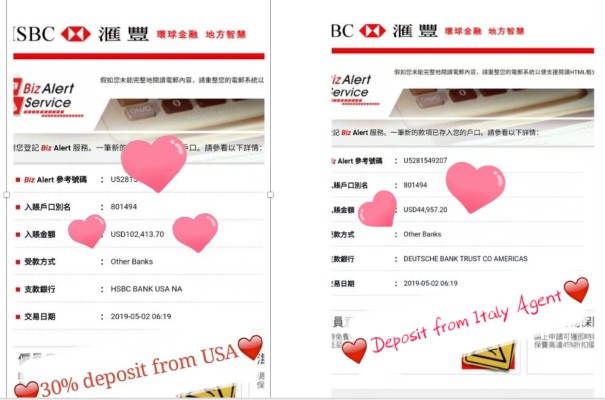

❙ Customers' Feedback

❙ FAQ

If You Could Not Find Any Similar Items You Want, You May Send Some Photos to Us. Because Our Catalog and Website Haven't Included All of Our Products.

❙ Yamaha Chip Shooter Video