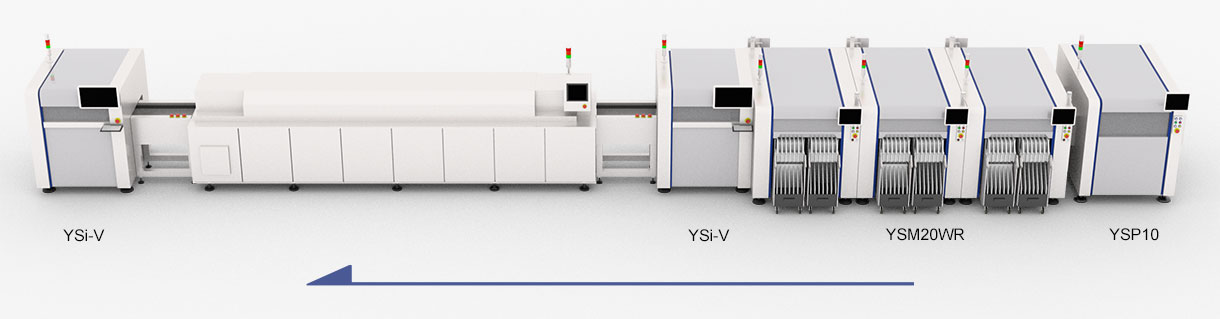

YAMAHA production line of industrial equipment

From: Author: Publish time:2021-09-07 09:25 Clicks:0

Proposal for production line of industrial equipment

High-speed and high-accuracy line that mounts components on large/heavy PCBs

High-speed and high-accuracy machines that mount components on large/heavy PCBs are needed.

Dealing with odd-shaped or tall components causes the operation to lose time balance and prevents increased productivity.

Changeover work including replacement of feeder carriages consumes much work and time generating a machine down-time.

(YSM20WR): High-speed high-accuracy mounting with a PCB size up to W742×L810mm and weight up to 10kg can be performed as a standard.(We offer custom designs for special equipments)

(YSM20WR): The HM head can handle a wide variety of components from 0201mm to W55 × L100 mm.

(YRM20): A relatively large number of installed feeders minimizes the changeover work count. Using easy-to-handle compact small carriages increases the work efficiency.

This line can perform high-speed and high-accuracy component mounting on any type of PCB. It allows to make flexible designs.

Producing various types of products is available. It maintains the cycle time for a wide variety of product types, which makes it possible to realize high productivity as a whole, In spite of the fact that it is handling odd-shaped or tall components.

This line reduces the burden of changeover work on operators, leading to improvement in machine operation rate and reduction in operational errors.

SMT Production Line Chm, SMT Line LED Display, Air PurifICation For Reflow Oven, Desktop Selecting Wave Soldering Machine, PICk And Place Machine With 8 Heads 66 Feeders, AutomatIC PICk And Place Machine For Pvc Foam Board, SMD PICk And Place Reflow Oven Machine Stencil Printer, SMT PICk And Place Machineder, Placement Machine, THT PICk And Placement Machine, UltrasonIC Cleaner PCB Generator, PCB Industrial UltrasonIC Cleaner, PCB Board Cleaner Crown, Vacuum Cleaner PCB Designer

Examples of customers’ problems and needs

Dealing with large PCBs

Dealing with odd-shaped components

Changeover work

Solution

Dealing with large PCBs

Dealing with odd-shaped components

Yamaha’s original technique of dramatically shortening the head traveling distance and dual-stage mounting enables high-speed mounting of odd-shaped or tall components.

Changeover work

Expected introduction effects

Dealing with large PCBs

Dealing with odd-shaped components

Changeover work