Surface Mount Technology | Yamaha Chip Mounter

From: Author:Yamaha Chip Mounter Publish time:2019-06-14 09:21 Clicks:0

Surface Mount Technology | Yamaha Chip Mounter

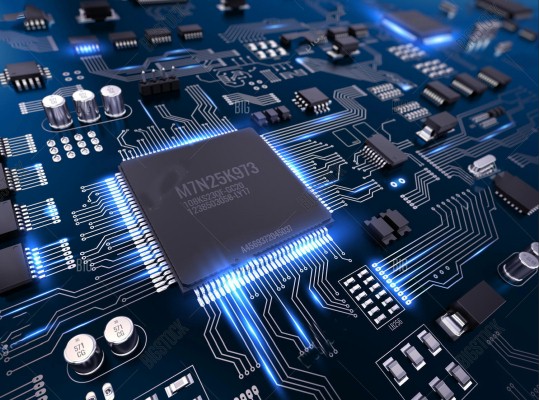

Surface-mount technology (SMT) is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards ( PCBs ). An electronic device so made is called a surface-mount device (SMD). In industry, it has largely replaced the through-hole technology construction method of fitting components with wire leads into holes in the circuit board. Both technologies can be used on the same board, with the through-hole technology used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors.

By employing SMT, the production process speeds up, but the risk of defects also increases due to component miniaturization and to the denser packing of boards. In those conditions, detection of failures has become critical for any SMT manufacturing process.

An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It may have short pins or leads of various styles, flat contacts, a matrix of solder balls (BGAs), or terminations on the body of the component.

Chip mounter is a very important part of surface mount technology, ETA supplying Yamaha pick and place machine, Yamaha smt mounter, Yamaha smt chip mounter, Yamaha chip mounter, Yamaha Modular placement, Yamaha smt machine etc.

And our main products is smt printer, reflow oven, chip mounter, wave soldering machine, and smt production line, dip/tht production line.

Know more smt process please viste our Youtube account: ETASMT

❙ Yamaha chip mounter video