YAMAHA SMT Machine Hybrid Placer i-Cube10

From: Author: Publish time:2021-09-06 11:55 Clicks:0

Hybrid Placer i-Cube10 Feature

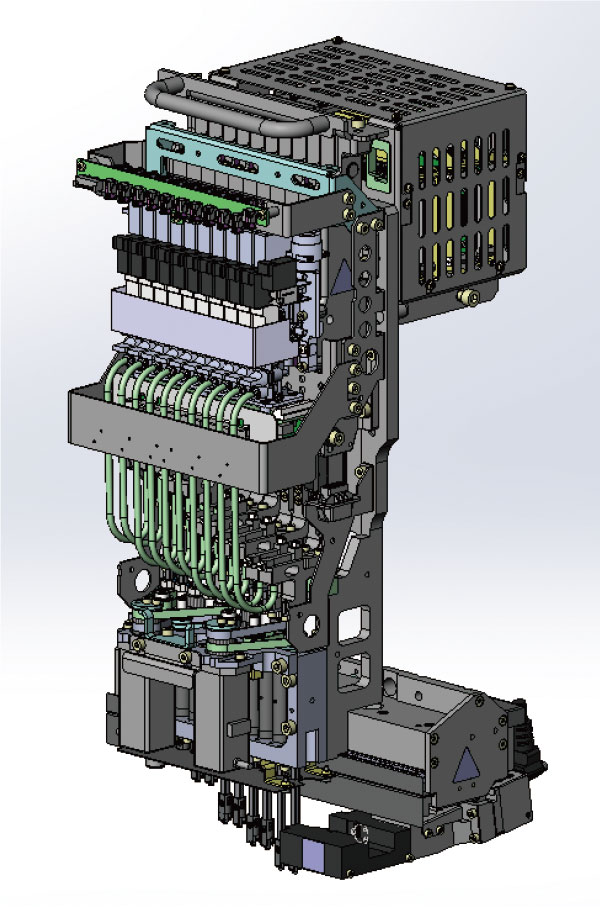

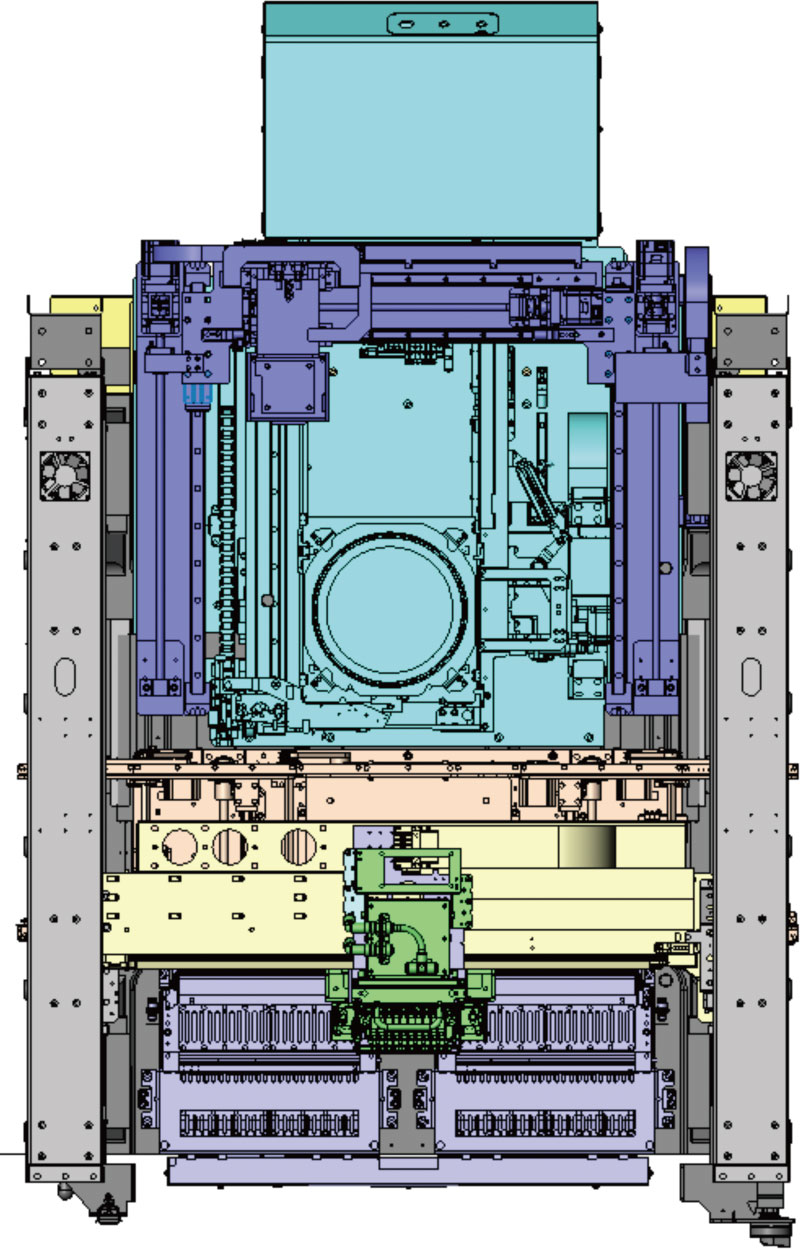

Yamaha proprietary hybrid placer, best suitable for module device, that consists of semiconductor and SMD.

It is capable of various types of the production process, and YRH10 realizes SMT for semiconductor, SMD in one unit. Post-mounting inspection is provided as a standard feature.

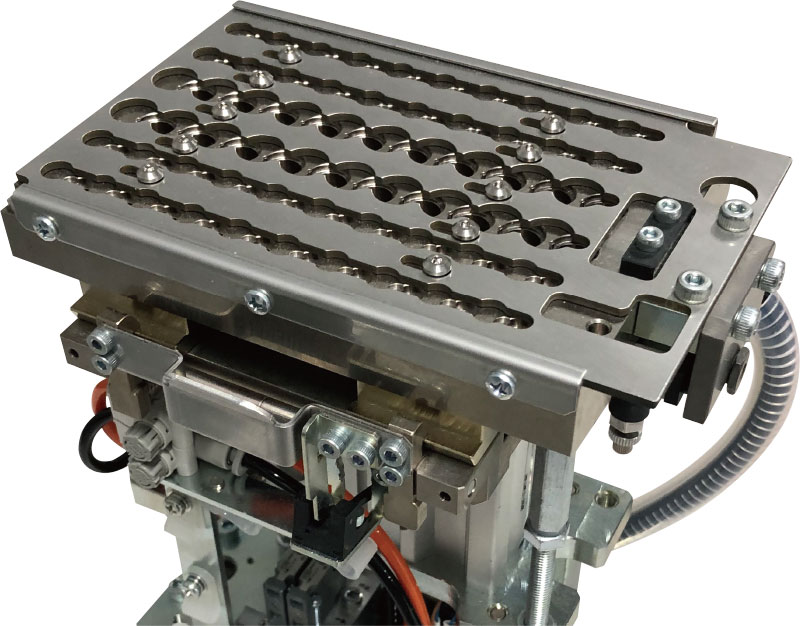

Placer with 10-nozzles on the mounting head realizes high productivity while maintaining high-level mounting accuracy.

High-speed flexible head covers from super-tiny components to middle size odd-shaped components. The adoption of a scan camera makes the operation distance from pickup to mounting shortest, which achieves high productivity.

Yamaha proprietary Compensation System realizes high mounting accuracy of ±15μm (μ+3σ).

Available for intelligent feeder which improves the pickup accuracy for tape reel component.

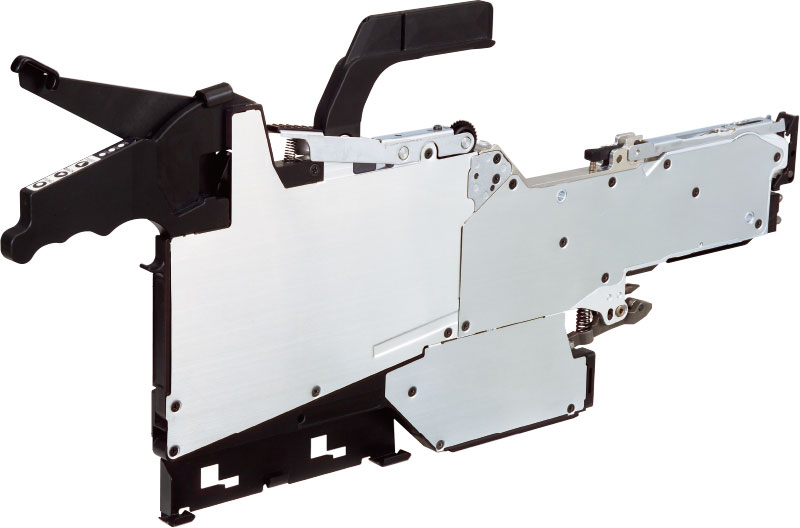

Available for electric intelligent feeder which are also used for machine. Compact and light-weight feeders improve the workability and reduces burdens to operators.

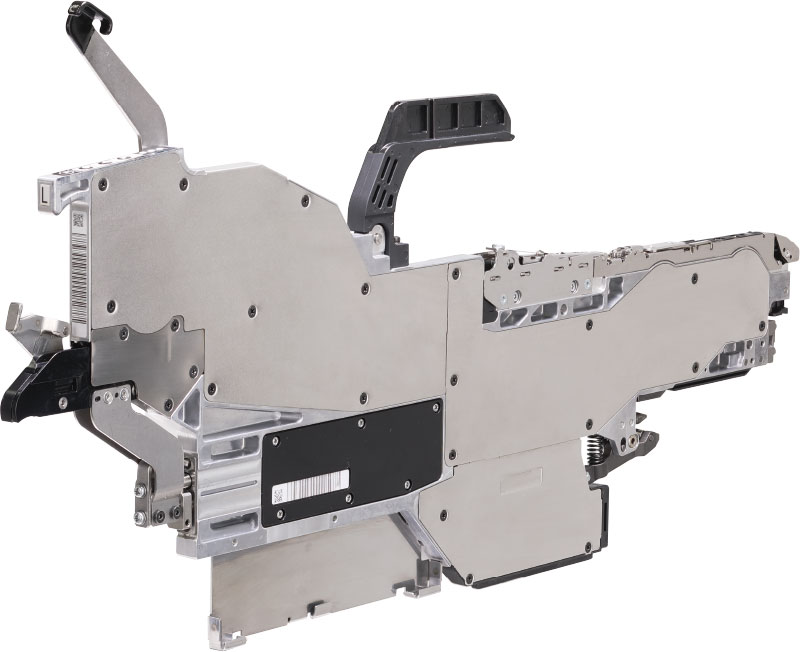

An Auto Loading Feeder for which two reels can be set in advance is also supported. This type eliminates the need for splicing and can vary the supply timing. This significantly reduces the decrease in the operating rate due to running out of components.

Available for nozzles stations, blow stations, and other options for various applications.

Customizable for various production layouts based on product types.

SMT LED Assembly Line, LED Light For Assembling Line, Dek SMT Solder Paste Printing Machine, Reflow Soldering Oven Machine, Fully AutomatIC Wave Soldering Machine, LED SMT Machine, SMD PICk And Place, StICker Placement Machine, Samsung SMT Machine, SMT Machine 3 In 1, AutomatIC LED Bulb And SMT PICk And Place Machine PrICe, LED PICk And Place, UltrasonIC Cleaner PCB Board, Liquid Cleaner PCB In UltrasonIC Cleaner PCB, PCB UltrasonIC Cleaner, PCBA Assembly ServICe UltrasonIC Cleaner

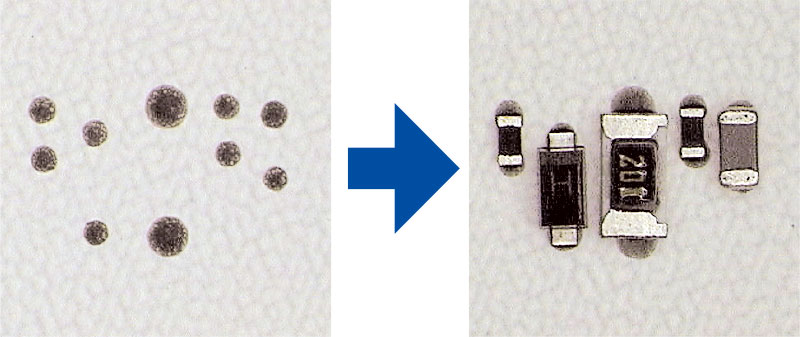

Mixed mounting of semiconductor and SMD

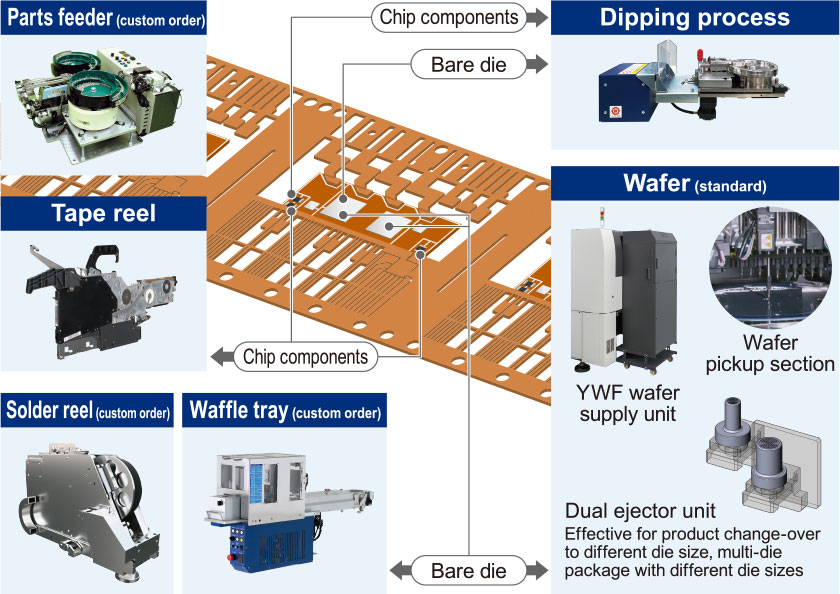

Supply patterns

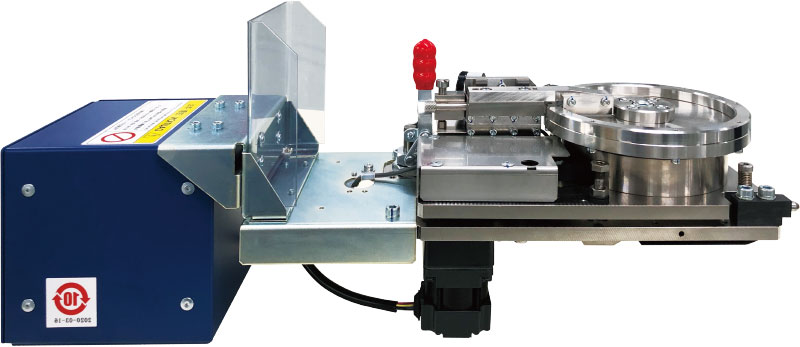

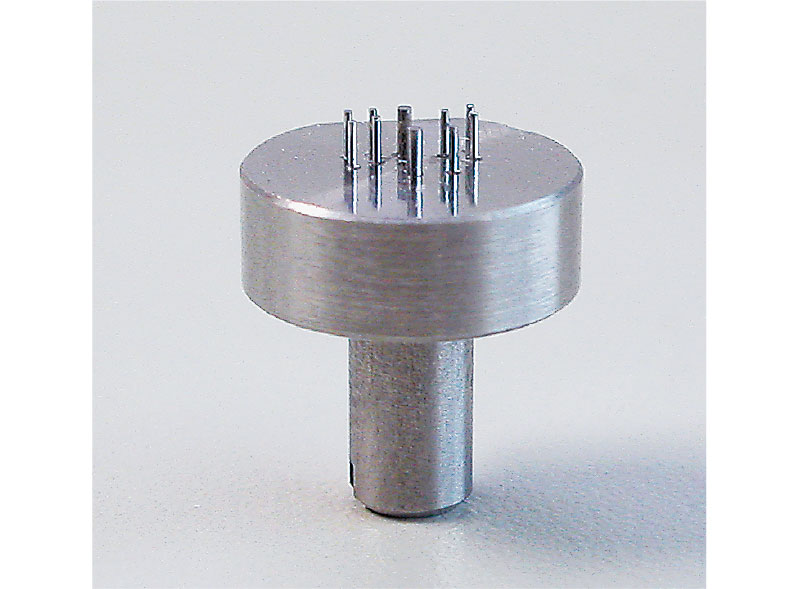

Pin transfer of adhesives (option)

Example of module component packaging process

Pallet types

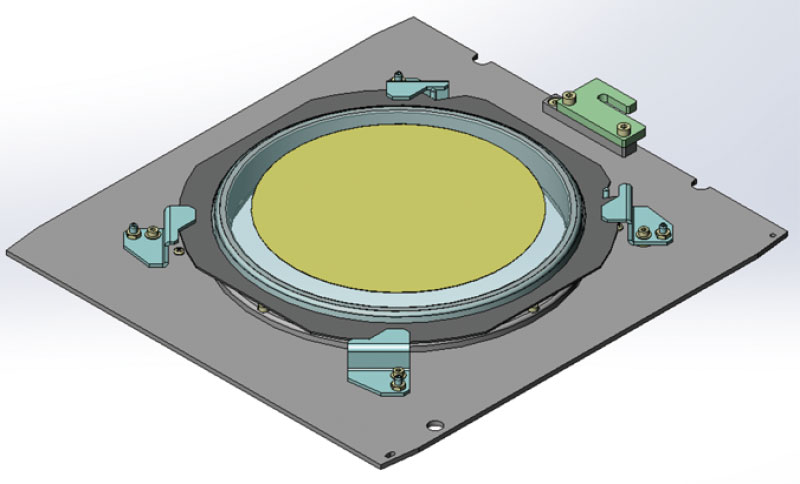

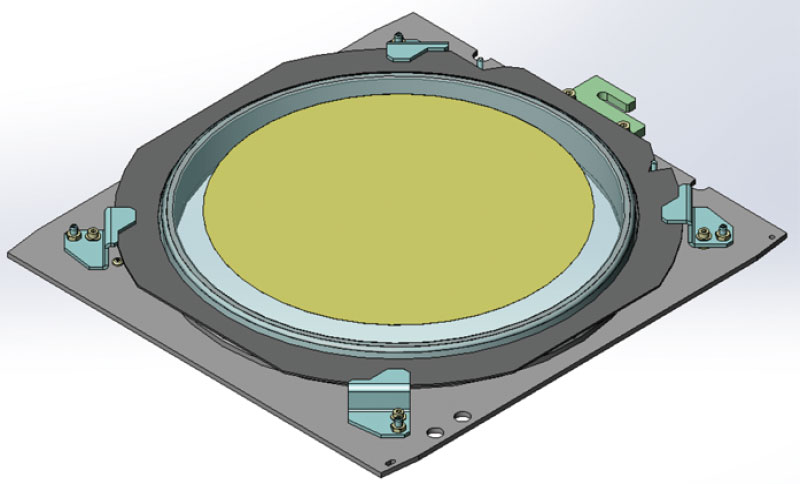

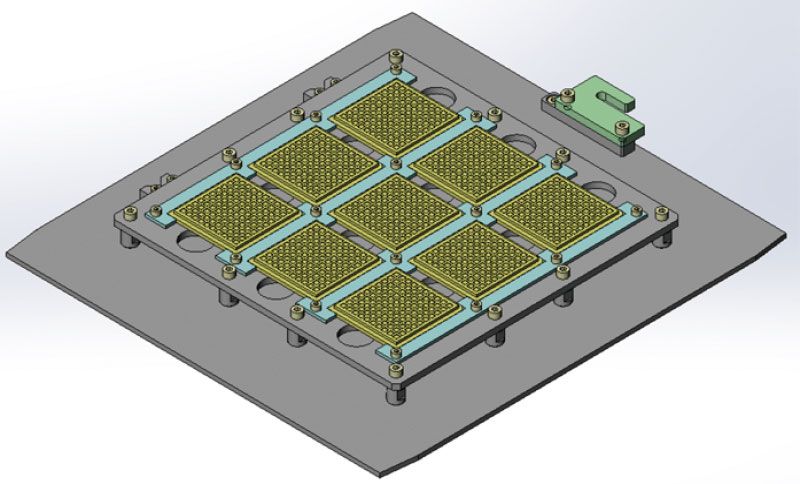

Wafer pallets (standard)

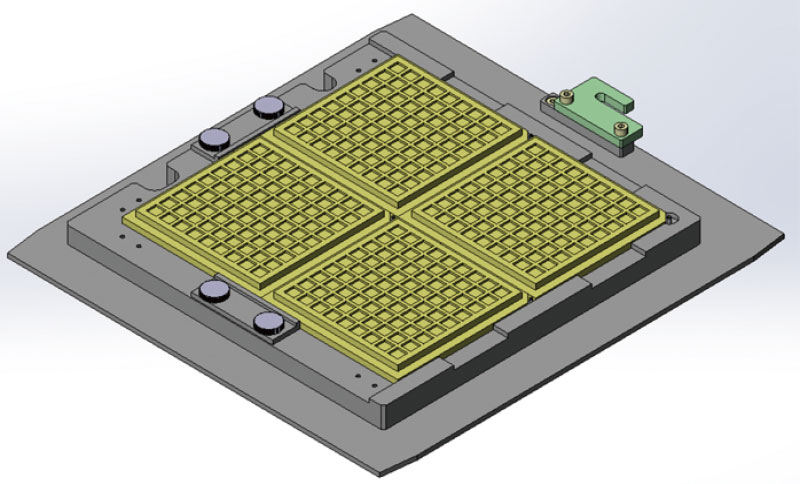

Waffle tray pallets (custom order)

Maximum settable number of pallets : 9

Maximum settable number of pallets : 4

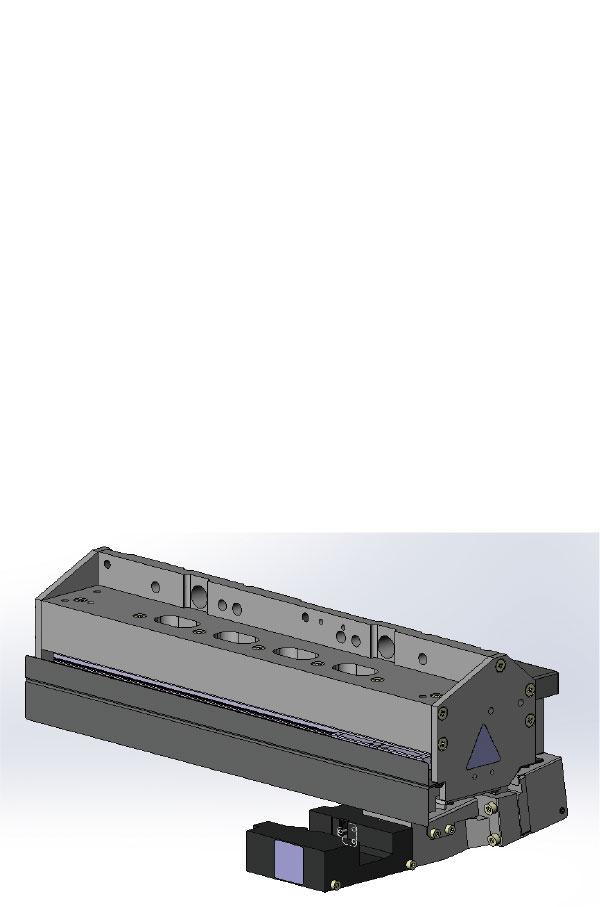

High-speed and high-accuracy mounting

Inline head with a scan camera

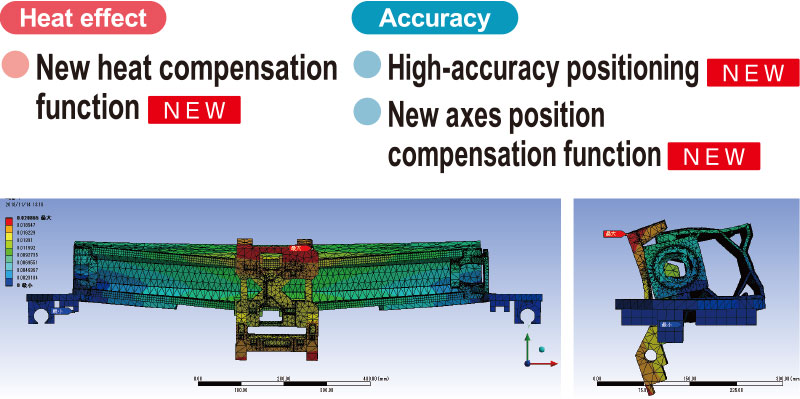

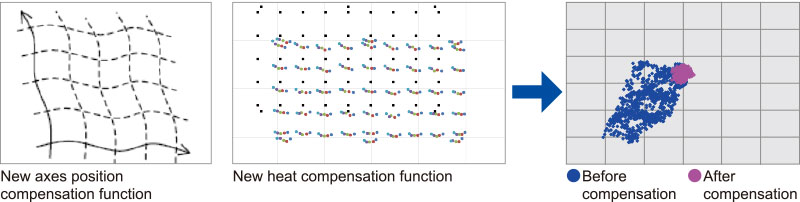

Multiple Accuracy Compensation System (MACS)

New compensation function + high-accuracy positioning

Available for intelligent feeder and various options

Combining with the Multiple Accuracy Compensation System MACS realizes high-accuracy component pickup and mounting.

ZS feeder

Auto Loading Feeder

Various options

Make automatic replacements of special and spare nozzles.

Applicable for various production processes

The highly productive flexible placer contributes to realizing highly efficient production processes.

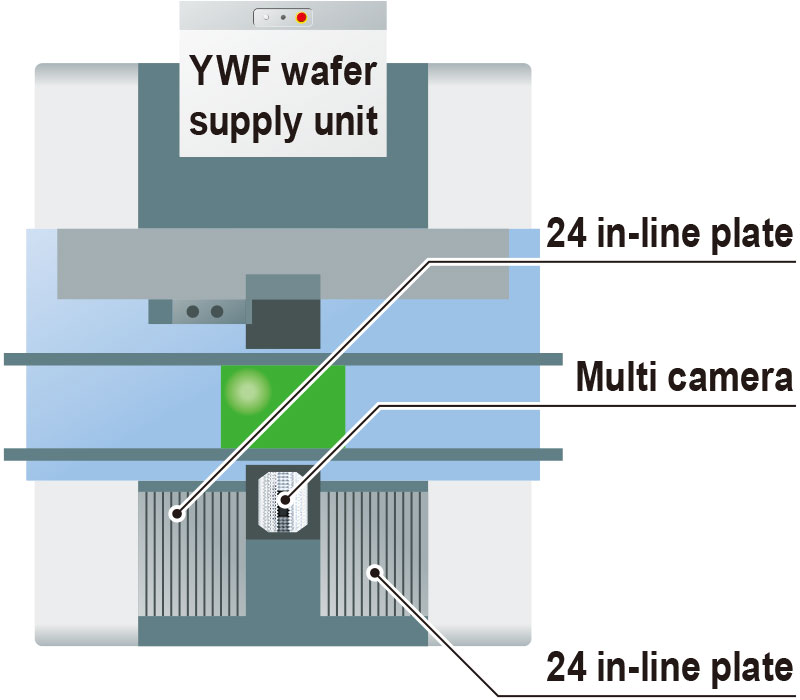

Standard layout

■Front:Feeder (24 in-line plate) x2

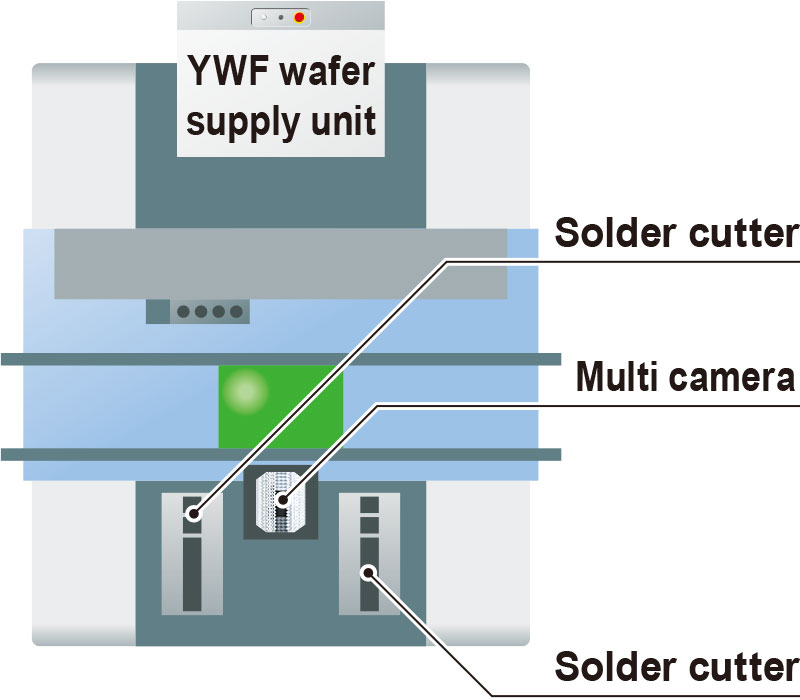

For power modules (custom-order layout)

■Front:Solder cutter x2

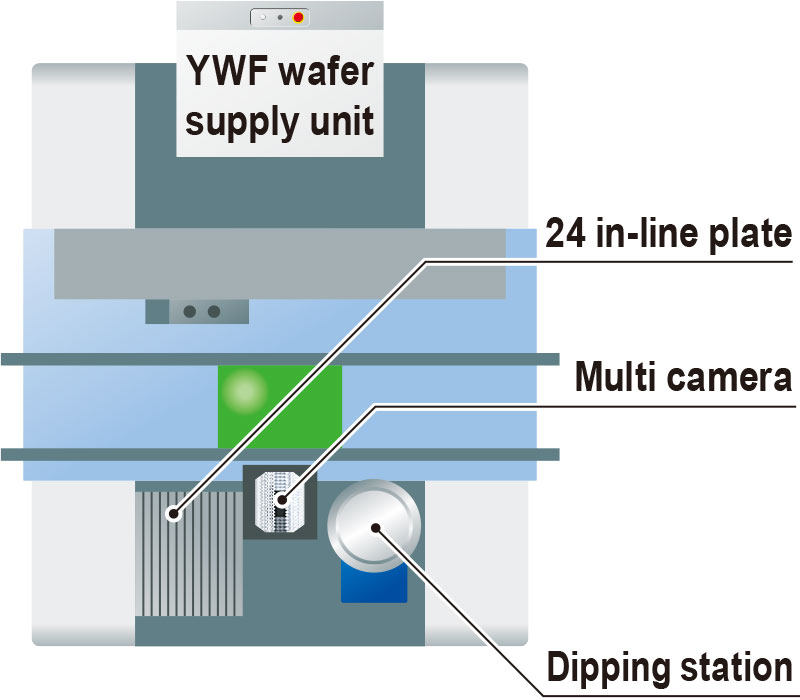

For MEMS sensors

■Front:Feeder (24 in-line plate) + dipping station