Premium printer YSP10 YAMAHA SMT MACHINE

From: Author: Publish time:2021-09-03 15:33 Clicks:0

Premium printer YSP10 Feature

World Class Speed and Performance! Capable of fully autonomous changeover tasks!

We achieved high productivity by totally redesigning the drive system to optimize the movement layout and cut the board transfer time to attain a cycle time including stencil cleaning of 12 seconds at the world's fastest level (optimal in-house conditions. Normal print time is 10 seconds.) reaching a speed 20% faster than conventional operation.

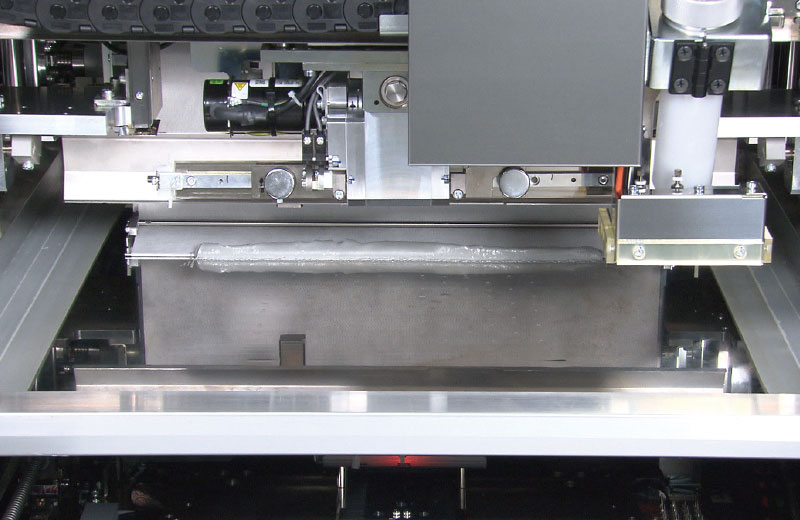

The function presets the stencil needed for the next production task while the printer is operating and automatically makes setups-changeovers. Space-saving design with small footprint sets and recovers used stencils all in one batch at the machine rear. This slashes the time needed for stencil replacement since workers can do stencil presetting in advance whenever they have time available without having to stop the printer. The squeegee head is now equipped with a new solder receiver plate to prevent solder from falling onto the stencil during replacement.

During stencil replacement, this function automatically scoops up solder paste remaining on the used stencil and swiftly transfers it to the new stencil now in place. Solder paste transfer takes place during auto stencil replacement while maintaining the rolling diameter which eliminates lost time and human error in setups and changeovers.

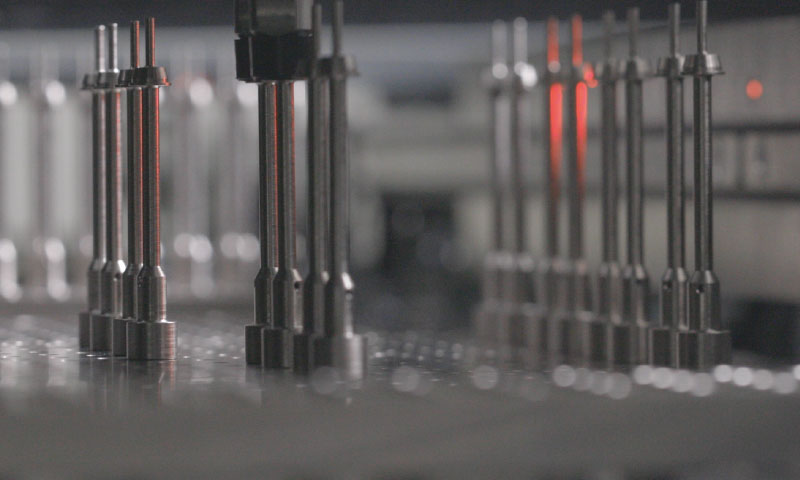

The function automatically replaces the push-up pins which support the PCB from below. Two gripper heads do high-speed replacements that not only slash setup/changeover times but also reduce human error. Even the large PCB such as 420x420mm can be supported by maximum of 200 pins with a margin. Pin layout can be set using mounter data and images captured by AOI, simplifying data creation.

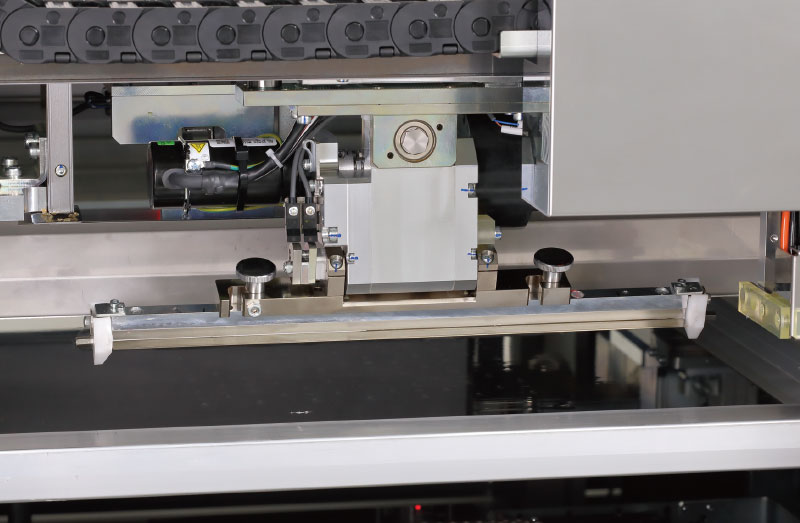

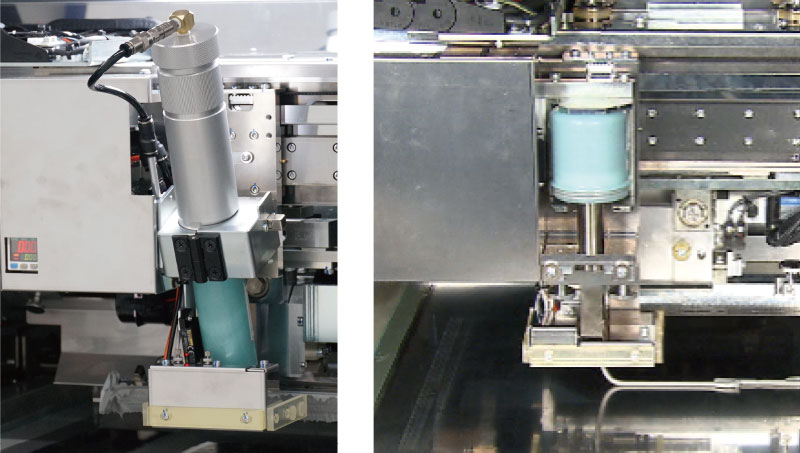

Program change squeegee attack angle and speed to an ideal setting to provide optimal printing conditions that match the solder being used.

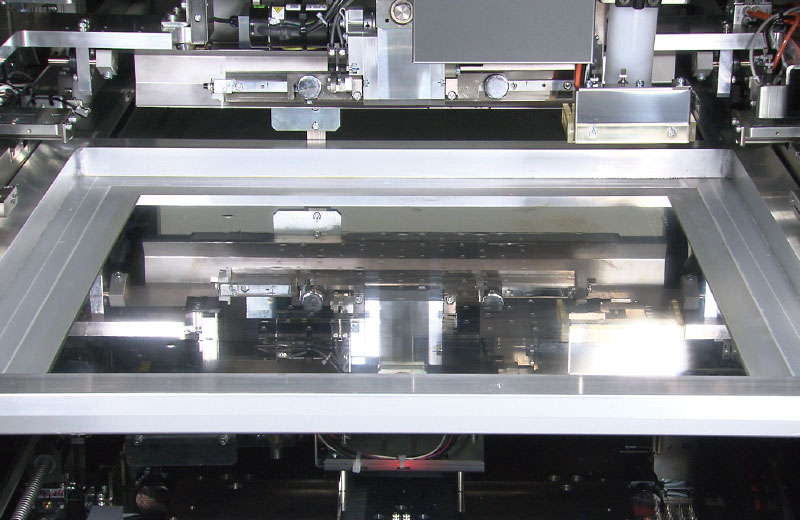

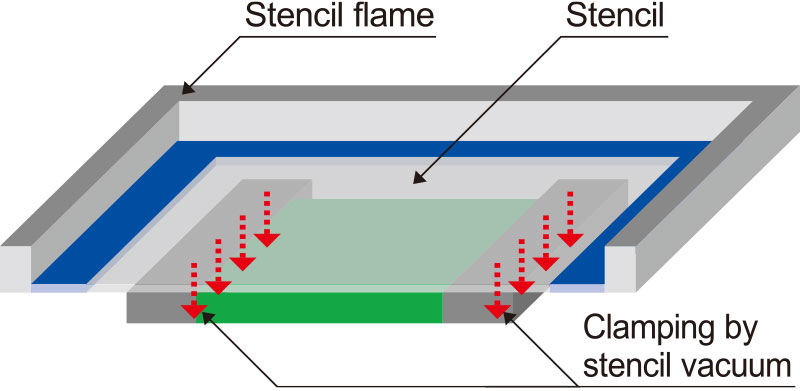

A stencil vacuum mechanism delivers consistent high accuracy printing with no effects from stencil droop. Also drastically cuts the setup time since no offset entry is needed during back and forth printing movement.

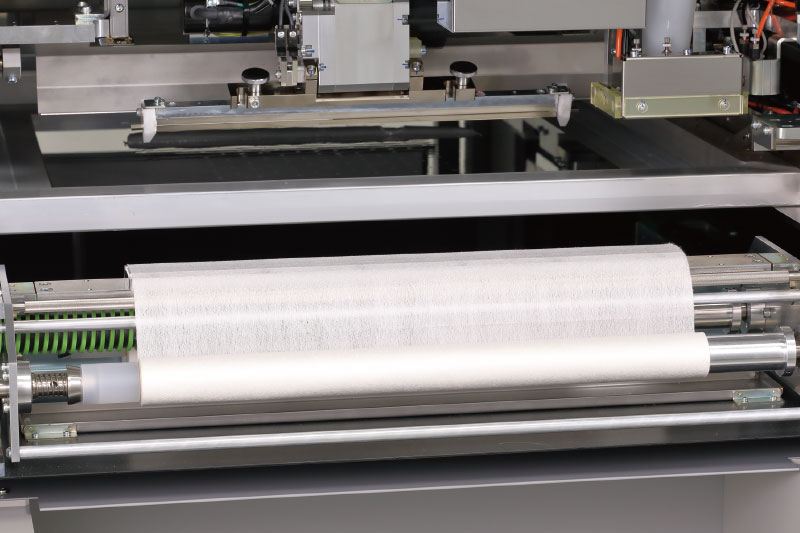

High efficiency cleaning system as standard equipment. New cleaner head ensures a huge reduction in cleaning cloth consumption.

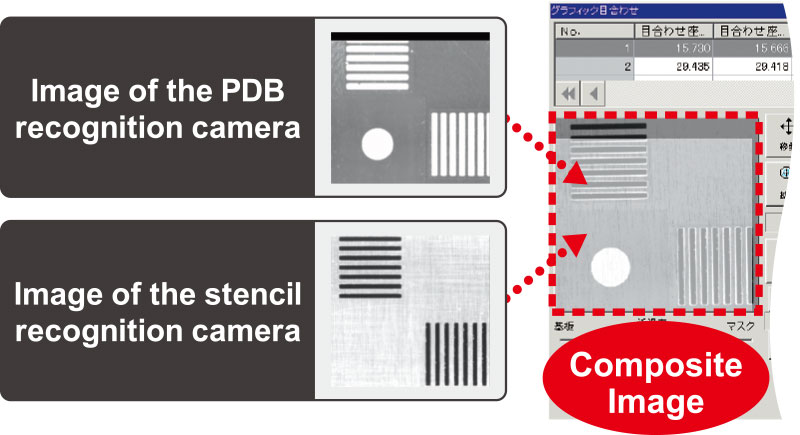

By images from two cameras are combined in layer, thereby operation of the PCB to printing stencil relative positioning can be performed simply and accurately.

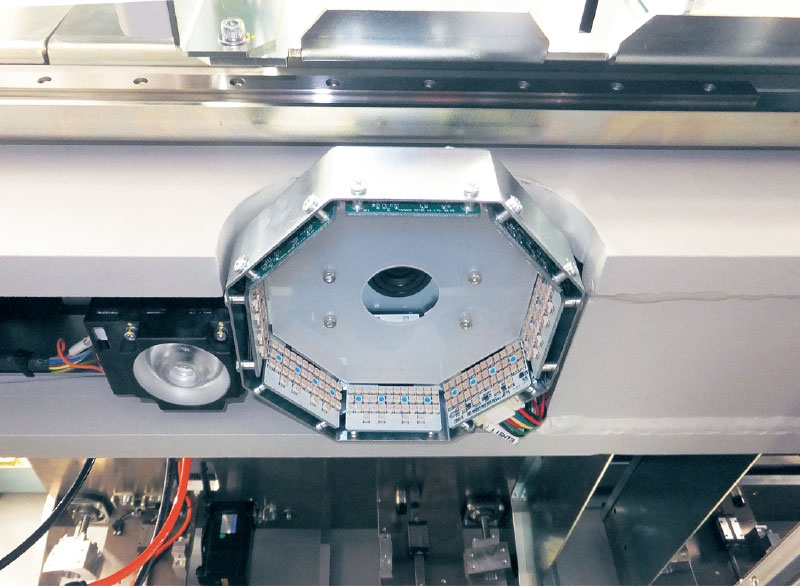

Supports full-on pro-level inspections with a dedicated camera. Feedback from inspection results allow over-printing and stencil cleaning.

Stabilizes the rolling diameter of solder paste that affects print quality. A newly developed 12oz syringe type PSC system realizes non-stop production for a long time.

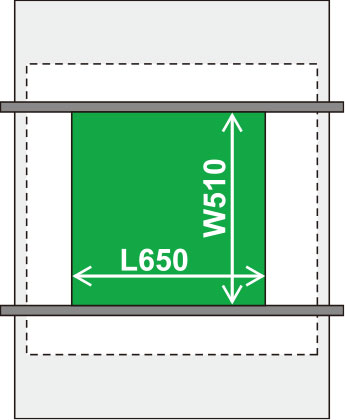

Expands large-size board support range from L510 x W460mm on up to L510 x W510mm boards. Also extends support range to include large-size mother boards including multiple smaller boards, large-size liquid crystal panel lighting boards and large-size industrial boards. Coverage of extra-large L610 x W510mm boards is available as an option.

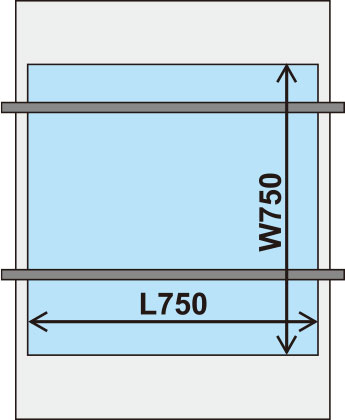

Supports L or large stencil sizes to maximum dimensions of L750 x W750mm. Instantly handles up to 5 stencil types sizes with just one touch.

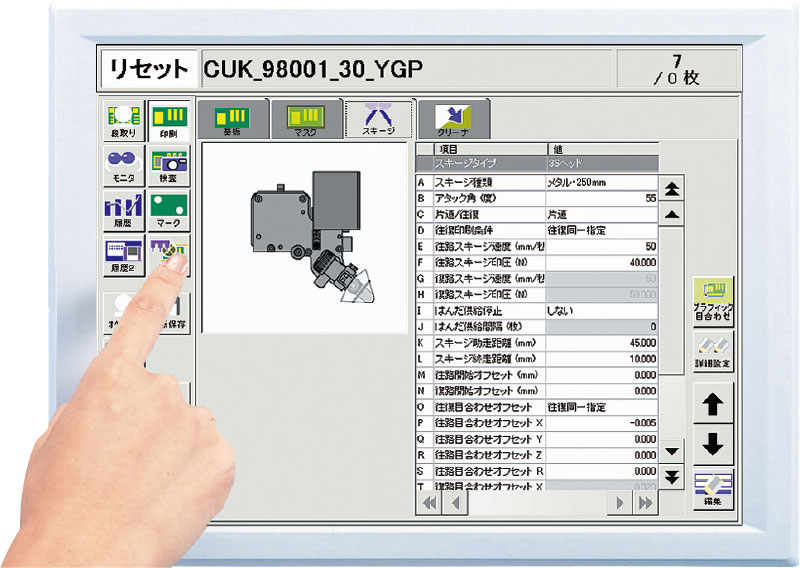

An easy-to-use and understand interface ensures smooth and sure operation. Display is switchable between 4 languages (Japanese, English, Chinese, Korean)

SMT Line LED, LED Light Assemble Line, SMT Line Standard AutomatIC Spray Printing Machine, Semi-AutomatIC PCB Stencil Printer, Hot Air Reflow Oven For PCB Soldering, Reflow Oven Medium Size, Soldering Machine PCB Mini Wave Soldering, AutomatIC SMD PICk And Place Machine, Roll PICk And Place Dispense Rfid, SMD PICk And Place Machine Full AutomatIC, SMD PICk And Place Machine With Solding, Pogo Pins PICk And Place Through Hole, PICk And Place Machine For LED Strip, Soldering Robot AutomatICglue Dispenser, Desktop Selective Soldering Robot, Soldering Robot AutomatIC 1000MM

Ultra Fast Cycle Time

Supports fully autonomous stencil exchange

Automatic stencil replacement(Option)

Automatic solder transfer(Option)

Automatic push-up pin exchange function(Option)

Delivers both high quality & super-accurate printing!

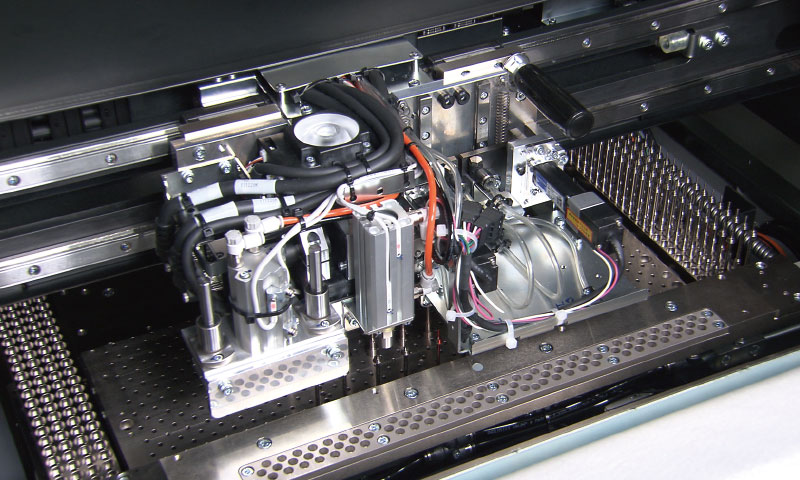

YAMAHA’s original 3S head[3S:Swing Single Squeegee]

Stencil vacuum

Auto cleaning system

Composite image alignment function

Print inspection function(Option)

PSC System (Option)[PSC:Print Stability Control]

Supports extra-large boards & large-size stencils

Supports extra-large boards

Large stencil sizes

Full range of options

Touch panel